Manufacturing

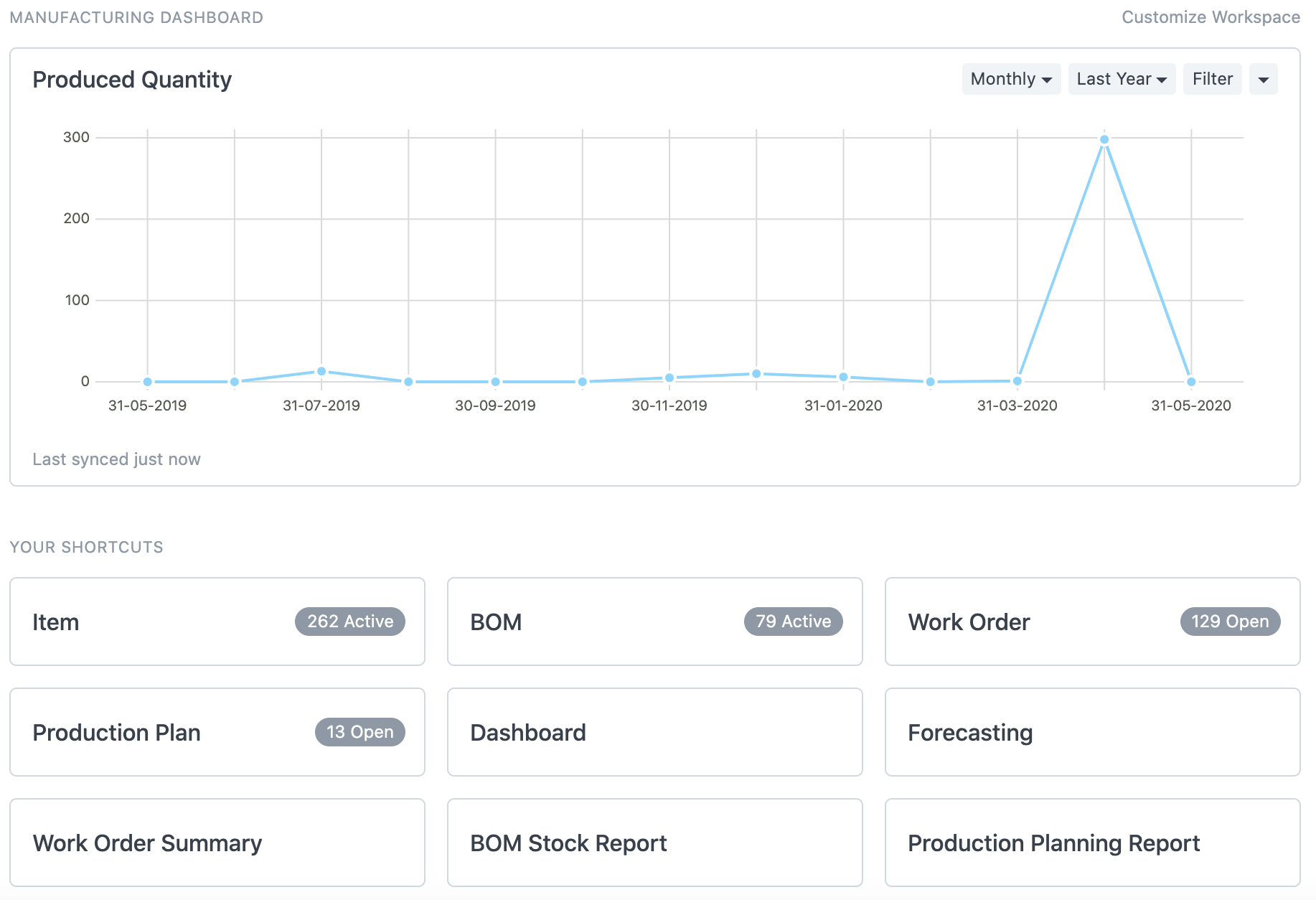

The Manufacturing module in ERPNext covers all necessary features a Manufacturing business would need. There are options to take a Work Order, enter stock of items, create a Production Plan, create a Downtime Entry, manage the Bill of Materials for Finished Goods / Template Items, generate reports, and more.

Different types of manufacturing like make to stock, make to order, and engineer to order can be managed in the ERPNext Manufacturing module.

1. Topics

1.1 Basic and Setup

1.2 Bill of Materials

1.3 Production and Material Planning

1.4 Advanced

2. Manufacturing Reports

2.1 Planning

2.2 Work Order, Quality Inspection & Job Card

- Work Order Summary

- Consumed Materials in Production

- Job Card Summary

- Quality Inspction Summary

- Production Analytics

2.3 BOM, Operations, and Maintenance

3. Articles

3.1 Production

3.2 Bill of Materials

3.3 Others

- Material Consumption

- Customer Provided Items

- How to change Dashboard in Manufacturing Desk

- Run MRP on Parent Warehouse in Production Plan